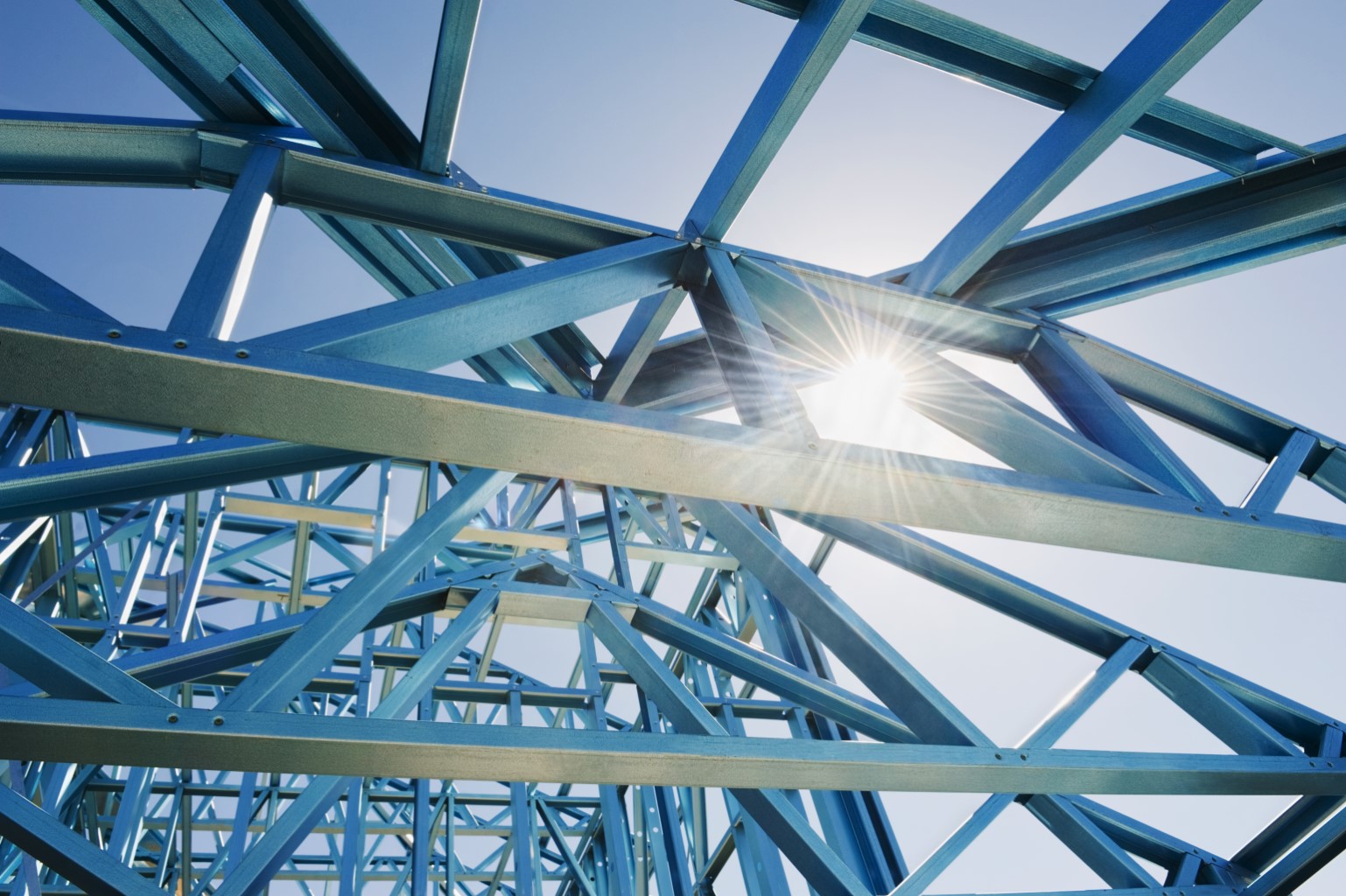

The system utilizes studs in the same way as stick-build SFS, except they are bolted together off-site to form story-high wall panels. Higher gauge studs and the Tekla designs allow structures to be constructed up to 10 stories in height.

ComFrame structures can incorporate concrete or steel joisted floors, depending on the client’s requirements.

ComFrame eliminates the issues commonly associated with Timber Frame construction. Timber is a living material. It expands when it absorbs moisture and shrinks when it dries out. This can and does cause problems for the owners of new homes built using timber frames. They can often experience extensive shrinkage cracking caused by the timber frame drying out and settling. The structure is often restrained by structural steelwork, causing lumps or bumps in the timber floors in areas with a large span.

There is also a problem when the timber studs warp, bowing out of line as the frame dries out, usually only after the heating goes on, causing hollows or bulges in finished walls. This is impossible to remedy without opening up the wall panel and replacing the affected studs. The CFS ComFrame eliminates all of these issues, leaving you with a maintenance-free, robust home or condo.

ComFrame delivers a high-quality building, but perhaps its most significant benefit is the speed of build. ComFrame structures generally take under two weeks per floor to construct, leaving you with a weathertight envelope allowing early access to trades.